Search

Robomotive gives eyes to robots to give you a helping hand. With these inexhaustible and versatile mechanical hands we help you lower the operational costs of your material handling processes

What does Robomotive do?

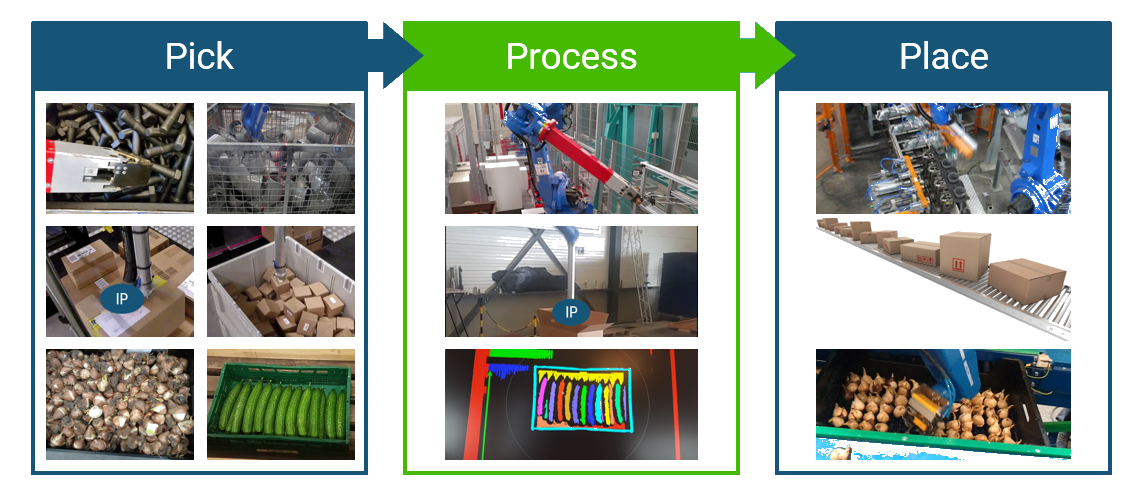

These mechanical hands can automatically pick, process and place products like humans do, 24 hours a day without a break

Our robots reach up to 1100 picks/hour

without the need for teaching or learning

How does Robomotive do this?

By mimicking the human eye-hand coordination with a

unique combination of robot, gripper and 3D vision

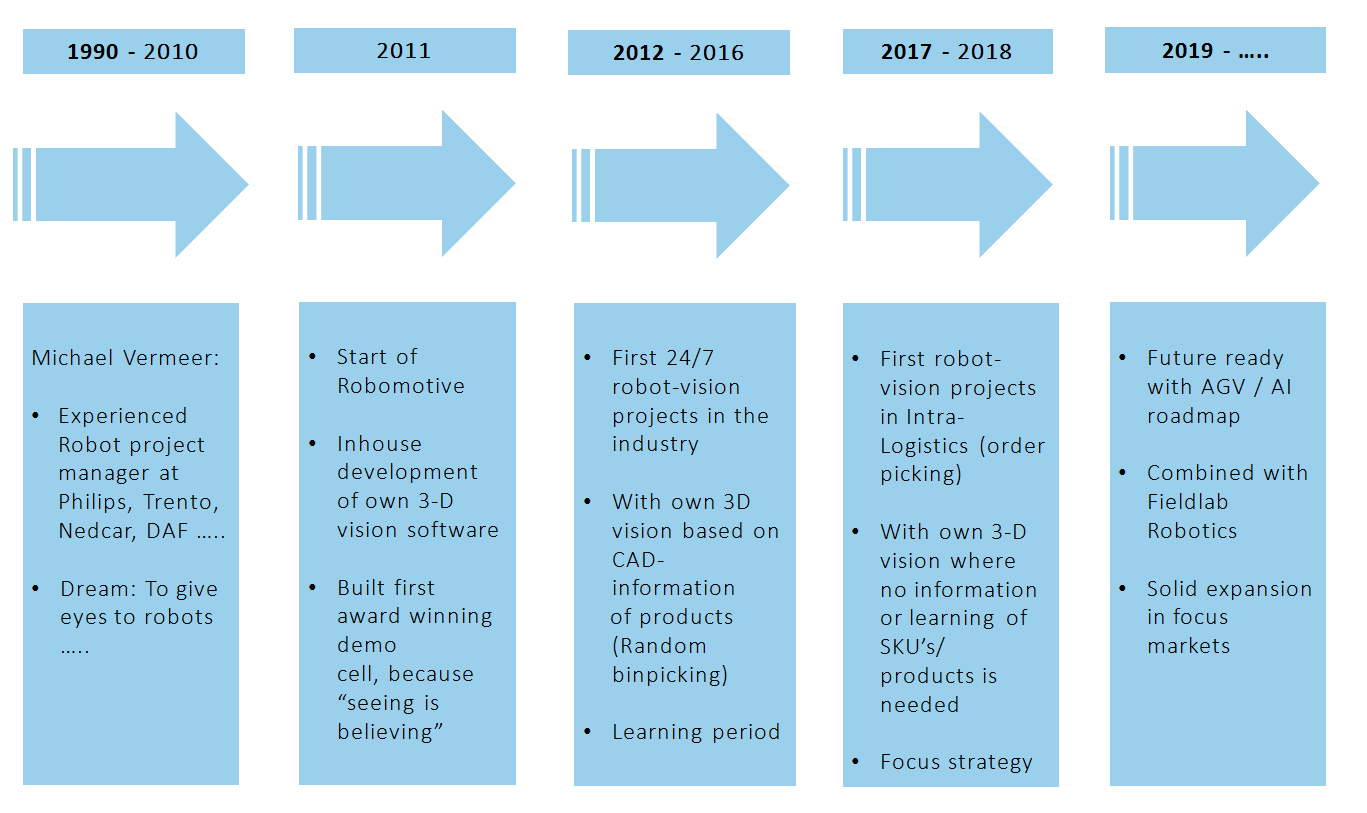

Based on >25 years of experience with integrating robust, reliable, maintainable and safe high-performance robot cells (mostly in the 24/7 Automotive world), and...

>7 years of experience with 3D bin-picking in the industry and

>3 years of experience with robotic order picking (intralogistics/ E-commerce)

With this award-winning, innovative team, always looking for new possibilities based on the future needs of our customers

By means of completely in-house developed modular software ready for every robot or 3D camera or gripper (with software already being >7 years proven technology)

By doing projects turnkey with a multidisciplinary team and by following a standard project approach (for one-offs and repeats)

Why robots?

The answer is simple:

There is a shortage in human hands

for doing this kind of material handling

Our robots fill this gap

With additional benefits such as: 24/7 employability , data-logging and possibility to spread ROI over more projects/ customers through high reusability of the technology

Who can benefit?

Our history

Awards and acknowledgements

2012

Hannover Messe

Third place Robotics Award

2012

Technishow Innovation Award

Nominee

2012

Innovation Award for the Province of Limburg

Nominee

2016

Nr. 1 Robotics Start-Up

of Europe and Nr. 4 World Wide (Robot Launch 2016)

2018

Founder of first official Field Lab Robotics in Limburg (Smart Industry)

2018

Turnkey delivery of first robotic picking cell in the world at DHL

Our mechanical hands

lower your operational costs

Companies that want to lower their operational costs by doing more work with the same amount of people

Logistics companies that want to grow, but can not find enough people for doing the material handling

Industrial companies that want to grow, but can not find enough people for doing the material handling or (un)loading of their machines

End-users in logistics and industry with the above-mentioned challenges

Machine builders with customers who have the above-mentioned challenges and who need a partner to integrate the robot-gripper-vision part into their machines

Component suppliers who deliver to machine builders or end-users who have the above-mentioned challenges

Picking can be done from randomly orientated unknown objects out of any kind of original packaging with high speeds up to 1100 picks/ hour

Processing can be separating, orientating, sorting, scanning, printing, but mostly transporting products from A to B

Placing can also be done to all kinds of packaging (like gitterboxes, europallets, totes, flowracks, etc) or into a machine

By means of completely in-house developed modular software ready for every robot or 3D camera or gripper (with software already being >7 years proven technology)

By doing projects turnkey with a multidisciplinary team and by following a standard project approach

Our mechanical hands

lower your operational costs

Companies that want to lower their operational costs by doing more work with the same amount of people

Logistics companies that want to grow, but cannot find the employees for doing the material handling

Industrial companies that want to grow, but cannot find the employees for doing the material handling or (un)loading of their machine(s)

End-users in logistics and industry with the above-mentioned challenges

Machine builders with customers who have the above-mentioned challenges

Component suppliers who deliver to machine-builders or end-users who have the above-mentioned challenges

All the above applications are robotics solutions turnkey delivered by Robomotive

The solutions vary from customers like UPS and DHL to customes like Unipharma and Kardex (end customer Sonepar). The applications can range from Item Pick (and pack if needed) from a goods-to-person system (like Autostore) to (un)loading of pallets or cagetrolley. The USP is that we don't need any "master data" about the SKU's and/or stacking pattern. The products can even by randomly placed within its source and can be optimally placed to the destination position.

A visionary dream becomes reality